-40%

CAMPAGNOLO, SHIMANO 1/4" AND 3/16" G10 440c STAINLESS STEEL F & R HUB BEARINGS

$ 7.22

- Description

- Size Guide

Description

THE HUBS, AXLES AND CONES ARE NOT INCLUDED. JUST FOR REFERENCE.CAMPAGNOLO, SHIMANO, NORMANDY

PACK OF 80

(2 EXTRA IN EACH SIZE)

VERY HIGH PRECISION CORRISION FREE GRADE 10 440c STAINLESS STEEL

LOOSE BALL BEARINGS FOR 2

FRONT AND 2 REAR VINTAGE HUBS.

IF YOU ARE ONLY REBUILDING ONE REAR HUB, YOU CAN USE THE EXTRA 22 1/4" FOR YOUR BOTTOM BRACKET!

THESE 440c G10 STAINLESS STEEL BEARINGS WILL OUTLAST AND OUT PERMORM ANY CHROME BALL YOU THROW AT 'EM.

Can be used for other

applications

SERIOUS INQUIRY BIKE BUILDERS.

La Grange 1/4" and 3/16" Grade 10 very high precision superior hardened 440c STAINLESS

steel ball bearings for your precious VINTAGE BICYCLE FRONT AND REAR HUBS.

PACK OF 36-1/4" FOR 2 REAR HUBS AND A PACK OF 40-3/16" FOR 2 FRONT HUBS.

(I ALWAYS GIVE 2 EXTRA IN EACH SIZE. YOU WILL RECIEVE A PACK OF 80)

USE OF YOUR ORIGINAL RETAINER OR LOOSE BEARINGS.

IN MOST HIGHER END HUBS; THE HUB CONE CUPS ARE MADE OF STAINLESS STEEL. THIS MAKES SENSE. PLEASE REFER TO PICS 6 AND 7.

Restoring your vintage hubs? or just wanting to replace those regular rusty chrome ball bearings with superior STAINLESS STEEL

CORROSION

FREE ball bearings?

A special bundle specifically put together for your precious vintage hubs. (THESE PACKS OF BEARINGS WILL REPLACE 2 FRONT AND 2 REAR HUB BEARINGS)

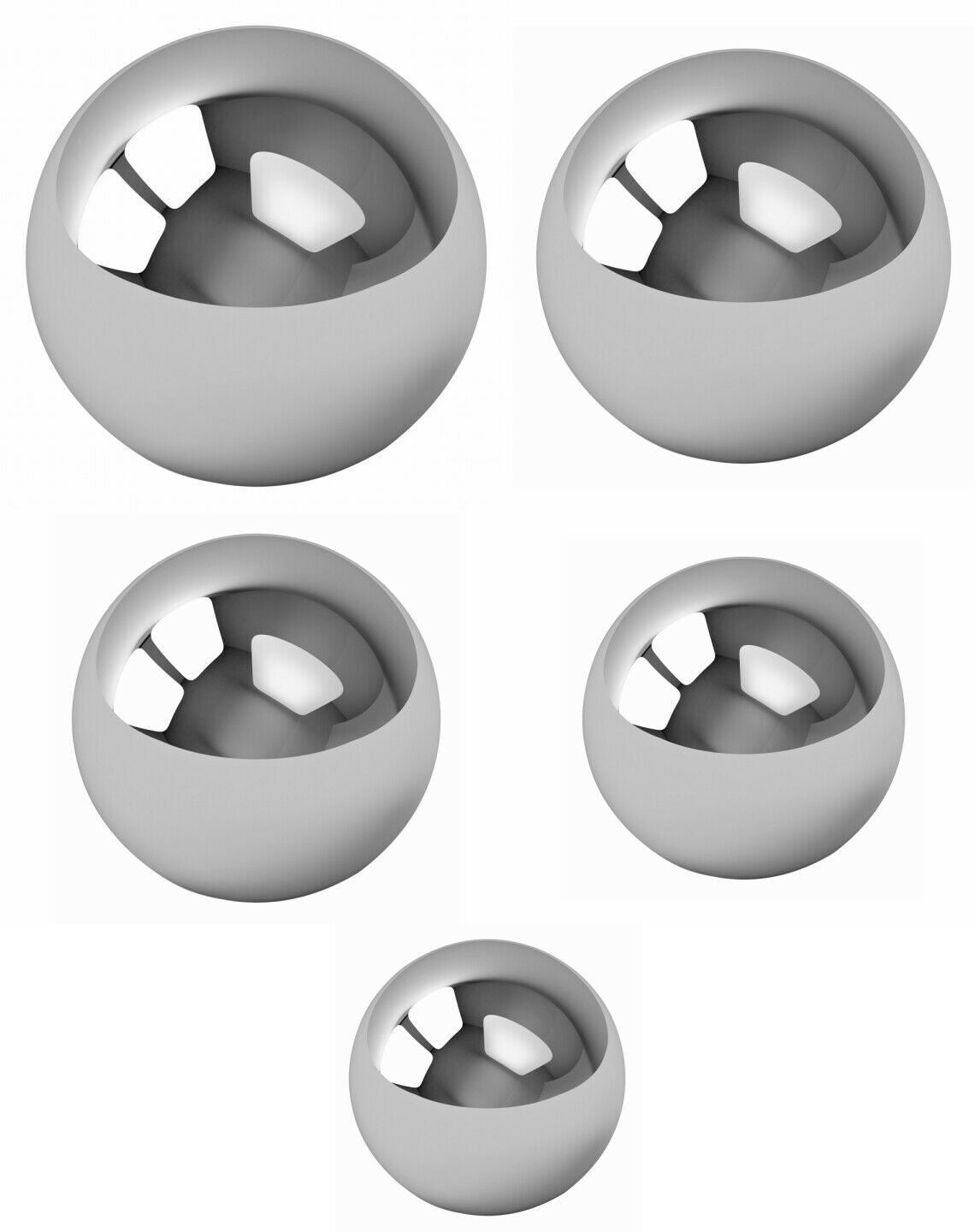

grade 10 is a higher precision than the regular 25 grade ball. The lower the number the higher the precision! There is no need to go better then grade 10, this will be overkill and these grade 10 are WITHIN the HRC 55 TO 65

HARDNESS SCALE.

a G10 ball of the same nominal size will have a diameter more closely matching the nominal, with just a ±0.0013 mm maximal deviation. Similar goes for other types of deviations (surface roughness etc.). The lower the grade number, the closer a ball is to a perfect shape.

I too was a serious road bike worrier when these type of hubs were on pro bikes. I know what it feels like to have superior bearings in my hubs, headset (5/32") and bottom brackets. Now you can buy a kit as this instead of buying a hundred or so bearings that you will never use or lose.

I do not recommend using these premium bearings in a Wal-Mart type bike.

TREAT YOUR HUBS WITH THE BEST GRADE 10 STAINLESS STEEL BEARINGS AVAILABLE.

WE ALWAYS GIVE 2 EXTRA IN EACH SIZE. YOU WILL NEED RUBBER GLOVES TO HANDLE THESE BEARINGS. GRADE 10 IS VERY SLIPPERY AND WILL GET AWAY FROM YOU.

PLEASE CHECK SIZE FOR ACCURACY.

TREAT YOUR HUBS WITH THE BEST GRADE 10 STAINLESS STEEL BEARINGS AVAILABLE.

W

e did a simple test. In the second too last photo; we let a g25 chrome ball bearing sit in salt water for 24 hours. The stainless steel ball bearing is on the right and the chrome ball is on the left. Which one would you want in your hubs?

If you are not satisfied with our bearings; we will refund your money in full and pay for return shipping. GUARANTEED!

For those who are familiar with ball bearings know that grade 10 are very high precision to where they are very slippery when handling them. These grade 10 bearings are made from 440c stainless steel for a lifetime of use! Chrome balls will ca-rode in time. Plus grade 10 stainless will spin faster than your regular chrome ball bearings and tolerate heat better at higher RPM. How many times have you opened up a set of hubs and the chrome balls lost the chrome and looked brown and rusty and also found rusty water coming out of your hubs. Not with stainless steel!

The differences between a Grade 25 and 10 bearing for cycling are noticeable and many companies use Grade 10 for this reason.

These additional tolerances provide greater precision and lower rolling resistance. (meaning: these will last longer and run smoother)

PLEASE MEASURE

YOUR OLD BEARINGS FOR PRECISION ACCURACY.

Balls are manufactured to the precision requirements noted in ANSI/ABMA Std. 10A for steel balls and ASTM F2094 for ceramic balls. These standards require that balls meet the limits for ball diameter, spherical form and roughness noted below for each grade level. Lower grade numbers denote more precise balls, which help to improve accuracy, reduce running torque and lengthen lube life. With few exceptions, NHBB manufactures its precision bearings with grade 10A and 10C balls or better. 440c stainless steel balls offer the precise geometry and fine surface finish that makes them especially useful for bicycles and many other applications with the added benefit of

corrosion resistance.

440 stainless steel is a high carbon martensitic stainless steel which has high strength, greater hardness and wear resistance then chrome balls. This type of stainless is capable of attaining, after heat treatment, the highest strength, hardness and wear resistance of all the stainless alloys. Unlike some stainless steel, this 400 series metal has a composition which allows it to be attracted to a magnet.

AISI type 440C stainless steel balls offer the maximum in material strength and superior

corrosion resistance

. They resist alcohol, water, many petroleum products, organic materials and steam. Type 440C balls are used in many applications including bearings, valves, locking mechanisms, fasteners and quick-disconnect couplings and are highly resistant to rolling-contact fatigue.

Balls are manufactured to the precision requirements noted in ANSI/ABMA Std. 10A for stainless steel balls

Standard Diameter: 3/16" / .1875 Inches

Metric Diameter: 4.7625mm

Grade: 10

Material: 440c Stainless Steel

Ball Weight (each): .01557 Ounces / 0.4413 Grams

Standard Diameter: 1/4" / .25 Inches

Metric Diameter: 6.35mm

Grade: 10

Material: 440c Stainless Steel

Ball Weight (each): .036897 Ounces / 1.046 Grams

Thank you for your support.

I am also a jazz musician and build my own family line of trumpets.

"La Grange Pro Trumpets"

I have the machines to make and round grade 10 bearings.

We are also the manufacture of the La Grange pro Trumpets.