-40%

Bearings Wheel Set For SRAM Pressfit GXP Bicycle Bottom Bracket Repair Parts

$ 8.07

- Description

- Size Guide

Description

Hubs Bearing GuideThe hub is the central part of your bike's wheels (front and rear), which connects to the wheel's rim via the spokes and through which the axle is fitted, enabling the wheel to freely spin on two sets of bearings.

As bikes have front and rear wheels, so too have they front- and rear-specific hubs. The front hub is simply designed to enable the wheel to spin, while the rear hub is a little more complex as it also forms part of the bike's transmission – the cassette or sprocket which drives the rear wheel is attached to the rear hub, which on most bikes also features mechanism to allow you to coast or freewheel (exceptions being fixed-gear or 'fixie' bikes and track bikes).

Your wheels spin more than any other part of your bike. Therefore, having the best bearings in this application is crucial to producing the best results

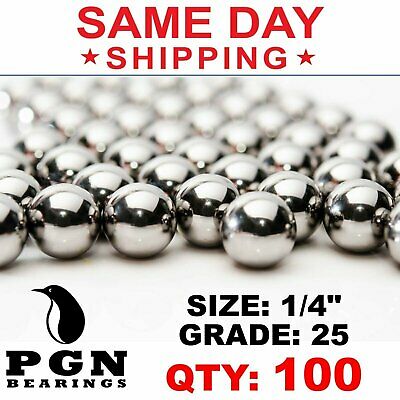

Item : FOR SRAM

1PC 22.2x37x8x11.5mm MR22237-2RS

1PC 24x37x8mm MR2437H8-2RS

The color of the seal is not sure. If you mind it, please contact us before you buy the bearing.

All about Headset Bearings:

1. How many different types of bearings are used in the modern day headset?

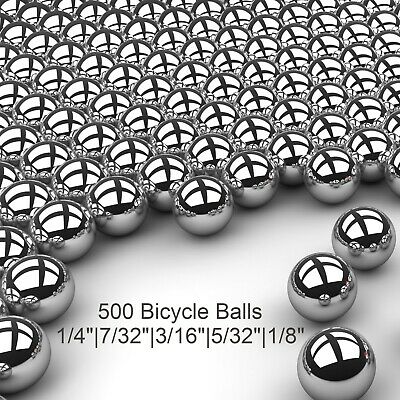

Answer: There are at least 6 different kinds of bearings used in the bicycle headset. They include; radial bearings, thrust bearings and angular contact bearings. These three types of bearings all use ball bearings. The second category of bearings is the roller bearings which include the standard roller bearing and the tapered roller bearing. Both of these use cylindrical rollers.

2. There are many different types of bearings. Which one is best for the bicycle headset and why?

Answer: Angular contact bearings are the most appropriate bearing for most headset applications. The primary reason is due to the fact that it is very efficient at dealing with the angular force that is exerted upon it. Whereas most deep groove industrial bearings are very efficient at dealing with vertical or horizontal loads, the pressing angle associated with the bicycle headset is much more angular.

Most of headset use big diameter axle to increase the strength. As the limited space, the bearing should have a big bore with thin wall of inner ring and outer ring to insert in. ACB has a primary advantage that reinforces axial loads over than deep groove ball bearings.

Angular Contact Ball Bearing is very efficient at dealing with both vertical (radial) and horizontal (axial) loads. Its great performances differ from other industrial bearing that only perform well in one direction. In many applications, ACB is used in pair due to its internal construction. It should be installed face to face or back to back in order to support the forces coming from any directions.

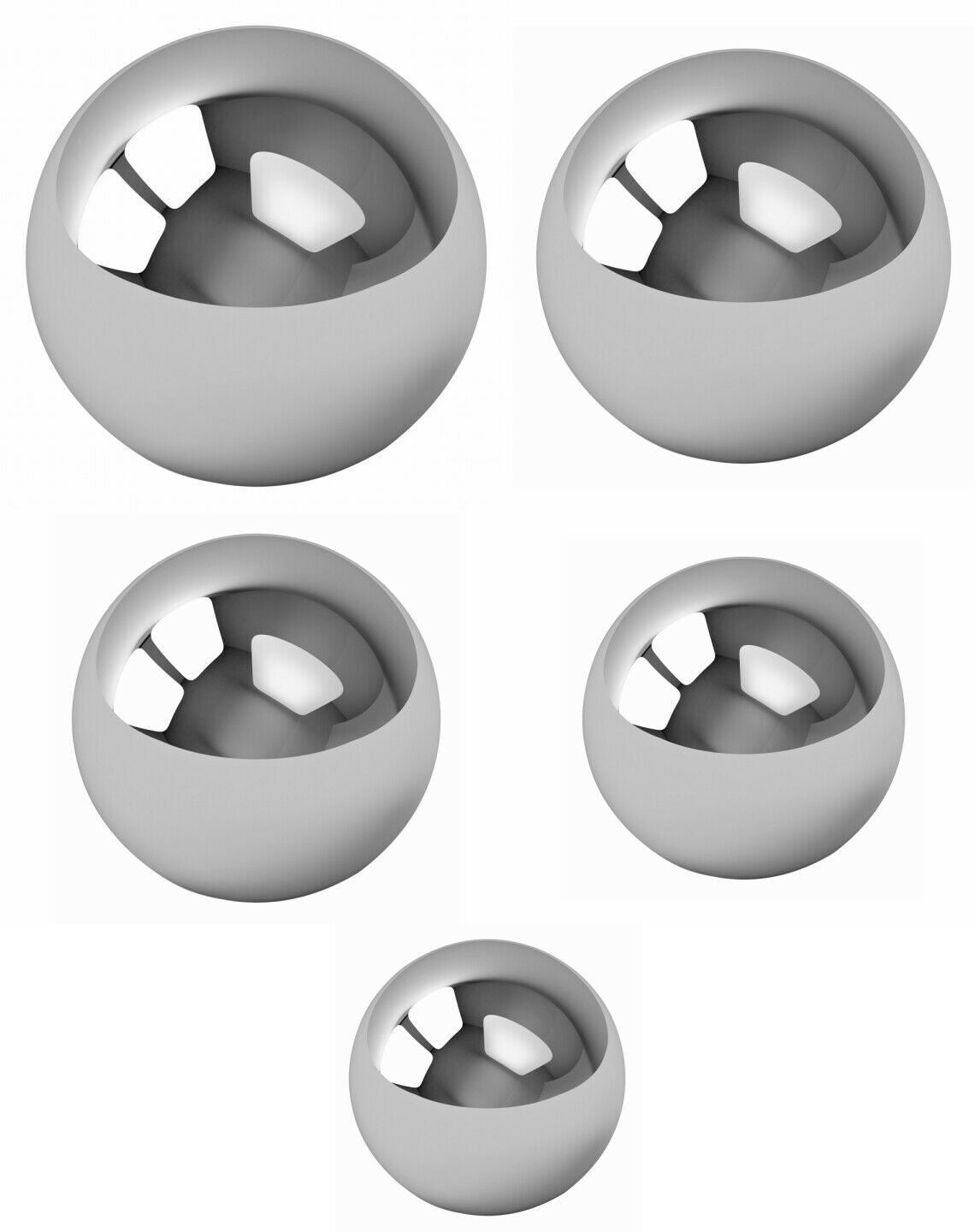

3. Are there different types of Angular Contact Bearings?

Answer: Yes. In fact, we makes four different types or grades of angular contact bearings. They are:

-High End ACB- We manufacturevery high-end angular contact bearings that feature stainless races and ball bearings, or Ceramic balls. While these bearings have a minimal chamfered area, because they press in to the headset cup, they offer superior longevity, durability and performance.

-Sealed ACB- Featuring highly polishes races, angled chamfer areasand high grade balls, FUSHI brand contact bearings come in a variety of sizes and grades, These bearings slip fit into headset cups or head tubes.

-Economical ACB- These sealed bearings have the same general features as above, but with precision ground ball races instead of the highly polished ball races. Designed for OEM applications, these bearings are reliable and durable.

-Serviceable cup and cone ACB- we both offer a serviceable ACB that can be disassembled, serviced and re-assembled. Utilizing a caged ball bearing race, these bearings are economical, serviceable and durable.

4. Are the various bearings interchangeable?

Answer: Sorry. The various styles/colors of bearings are not interchangeable. Damage can result to your frame or headset if the wrong replacement bearing is installed.

5. What if my bearings are old and dirty and I can not tell what size the bearing is?

Answer: FUSHI offers a headset bearing gauge that will help to identify the type/size of the bearing and/or the sizing of your integrated style headtube.

6. My bicycles are sold in areas that have very adverse and wet weather. Does fushi offer a bearing that is more rust and weather resistant?

Answer: Yes. we also offer stainless steel version with stainless inner and outer races as well as stainless ball bearings.

7. What are micro spacers and how are they used?

Answer: Micro spacers are 0.25mm thick and fit between the compression ring and the top cover. Integrated head tubes are specially machined to accept proprietary bearings.

Due to frame manufacturing tolerances, the vertical height of the bearing pocket can very resulting in an imperfect fit between the top of the head tube and the headset top cover.

Any number of Micro spacers can be used in order to achieve the correct clearance.

FAQ

1. Why do the bearings I receive have shaking?

The clearance of the bearing is related to the play.

The default is the standard C0 clearance, which is usually 3-18um.

The corresponding principle is shown in the figure below.

If you don't need to shake, please choose C2 small clearance bearing,

If you have any questions, please contact us before purchasing.

2. What is the accuracy of ABEC-1?

ABEC is the American ANSI standard.

The corresponding German DIN standard and international ISO standard are as follows:

3. Do you provide logistics tracking information?

Yes, all our products provide full logistics tracking.

And the products you buy are all new.

We will buy transportation insurance for you.

If the product is damaged or lost during transportation, you can get paid.