-40%

6900 Hybrid Ceramic Bearing 10x22x6 mm Bicycle Bottom Brackets & Spares 6900RS

$ 4.06

- Description

- Size Guide

Description

WHAT IS A HYBEID CERAMIC BEARING?A ceramic hybrid bearing is a combination of ceramic balls and bearing quality steel rings. Which combine hardened steel rings with rolling elements made of high-performance ceramic materials, are an increasingly popular option for demanding applications.

TECHNICAL SPECS

Model: 6900 RS Structure: Deep Groove Ball Material: Hybrid Ceramic Bore Dia (d): 10 mm Outer Dia (D): 22 mm Width (B): 6 mm Clover: Sealed (2RS) Lubrication: Grease Clearance: C0 Quantity: 1 Lot = 1 PC

Special Note:

--- 1, Sometimes the cages will be different. eg.: 67 series thin-walled bearings, because the inner wall is very thin, will use the crown-shaped iron cage. --- 2, The grease and sealed are accept custom-made, so sometimes there are different colors of the rubber sealed. If you mind the sealed color, please contact us. We'll confirm the stock for you. --- 3, The standard clearance of bearings is ISO standard C0, the United States standard K25, the clearance value is 3-18um; If you have special requirements for swinging, please contact us before purchasing to confirm.

This Bearing Structure

Standard Type: A ball bearing is composed of an outer and inner ring, balls, seal and a retainer. 52100 Chrome Steel Outer Ring & Inner Ring + Si3N4 Ceramic Balls + Nylon Cage + Grease + Sealed = Hybrid Ceramic Bearing

This Bearing Cover

Compared to the open type, the shielded and sealed bearing types provide better protection from contamination and grease leakage. They are selected based on the application type and environment. This is 2RS double sealed.

This Bearing Lubrication

One of the most important elements required for the effective function of bearing arrangements is correct lubrication. The lubricant separates the metallic bearing surfaces and thereby reduces friction, preserves the steel parts and acts as an additional barrier against the entry of contaminations or impurities into the bearings.

This Bearing Cage

Retainers keep the balls separated and equally spaced. Retainer types are set based on the bearing size but can be selected based on the required performance. This is made of Nylon PA66 Cage.

This Bearing Material

The most common material used to produce the load carrying components in roller bearings is 52100 chrome steel (bearing steel). These components are the bearings inner and outer rings, balls and rollers. The chemical composition of this steel has high carbon and about 1.5% chromium content. Using controlled processing and heat-treating methods the finished bearing components have high strength to resist cracking and a hard surface to resist subsurface rolling contact fatigue. The typical surface hardness for bearing components made from this material ranges from 60- 64 on the Rockwell hardness C scale (Rc).

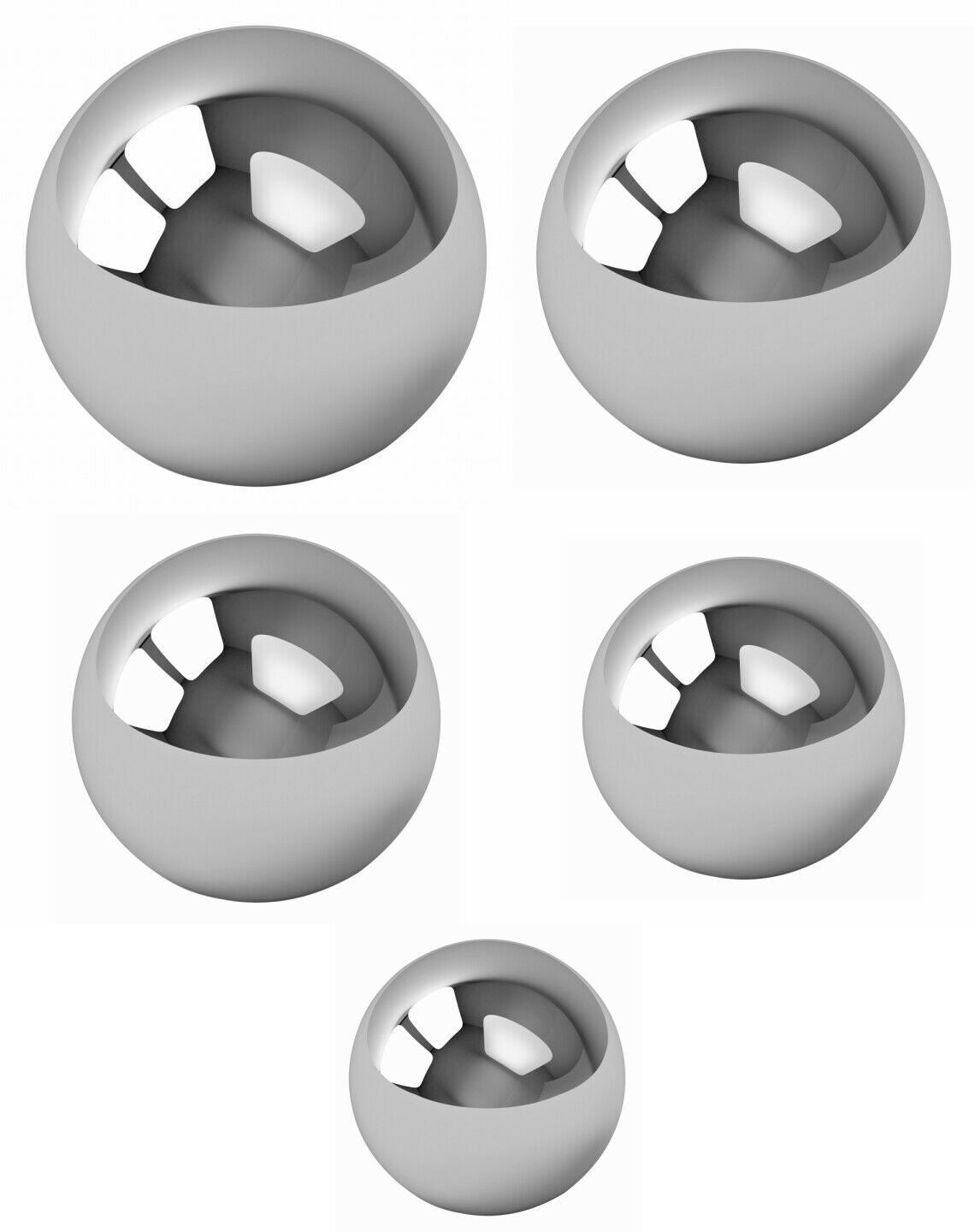

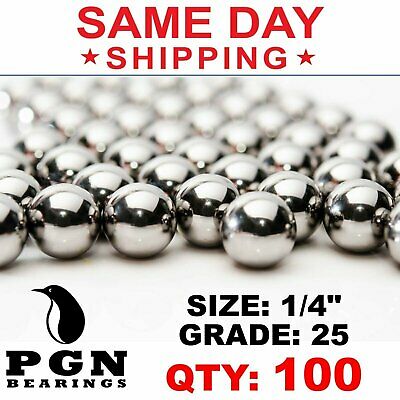

This Bearing Balls

Due to this usually very small contacting area ball bearings have less frictional resistance and are more suitable in high speed applications. This is made of Si3N4 Ceramic.

This Bearing Clearance

The term “clearance” is briefly described as the distance that bearing components may move relative to each other at physical extremes. CN (C0) “normal” clearance This clearance group is defined as the standard. Thus CN is not marked on the bearings. Historically the standard clearance was designated as “C0“. C2 clearance range smaller than CN C3 clearance range larger than CN

This Bearing Grade

Executive standard: GB/T 307.1-2005 Rolling bearings Radial bearings Tolerance

MORE BEARINGS DETAIL

Applications: Bicycle Hub